n this post I will explain why it is important to apply sufficient primer in the correct way and what mistakes we tend to do when applying it.

One of the biggest mistakes we do when painting, is not applying enough primer.

IF IN DOUBT – OVER APPLY

A thick coating after a good surface preparation will last longer than a thin coat after a GREAT surface preparation

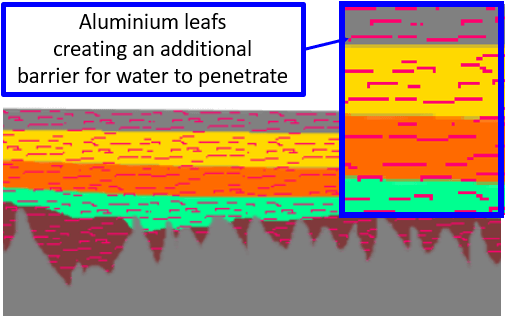

The paint is creating what is called a barrier effect, keeping moisture away from the steel.

If this barrier is not holding, all the hard work of applying it will soon be lost.

The aluminium leafs will increase the distance the water will have to travel to reach the steel.

Most top coats do not have this, making their protective value significantly lower.

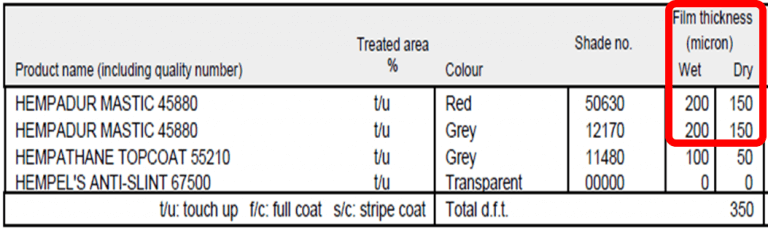

Coating thickness:

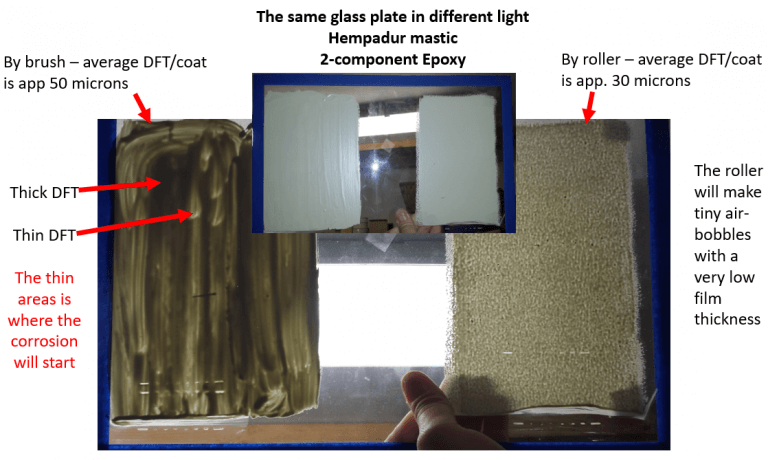

Different means of application gives different average thicknesses and penetration into the surface.

A brush will give app 50 microns Wet Film Thickness. In addition to this it will penetrate better into the steel surface.

A roller will give app 30 microns Wet Film Thickness.

It should definitely NOT not be used for the first primer coat as it will not penetrate into the steel profile “valleys”.

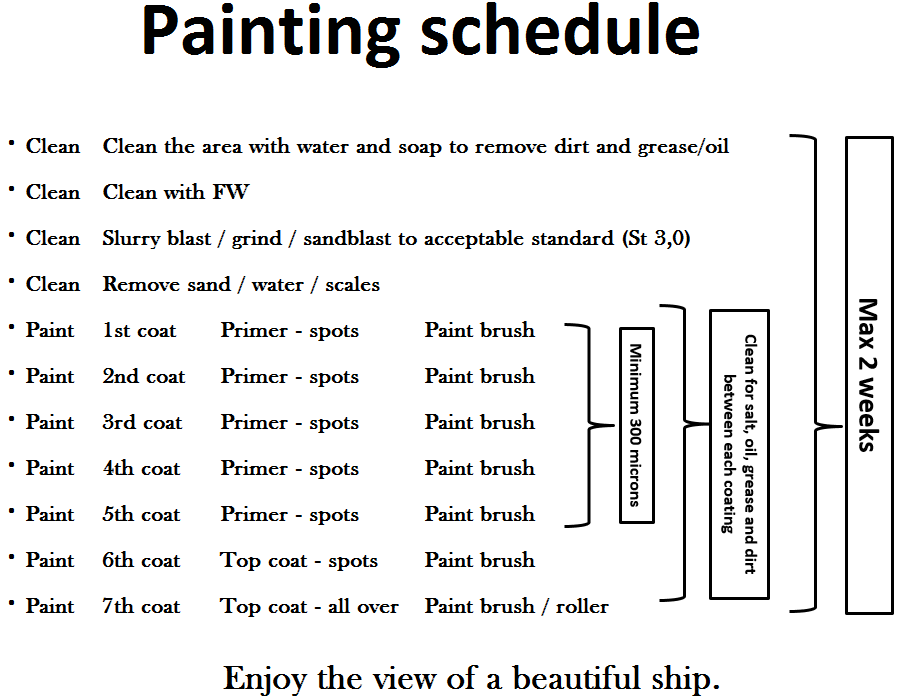

We need +300 dry film thickness of primer to adequately protect the ship.

Hempel Maintenance Manual advising 2 coats of 150 microns DFT.

This is frequently misunderstood onboard, and 2 coats by roller is applied thus only applying 60-100 microns.

When painting with brush:

- Give a good thick layer

- Make sure you mix a little more than you need. We tend to stretch the last ½ liter and then under-apply.

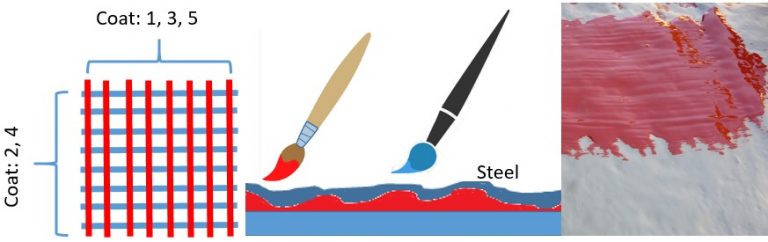

Make sure that each coat is diagonal on the last

The brush will make ”peaks” and ”valleys”, but by painting perpendicular. You will fill the ”valleys” of the previous coats.

If there are any doubts to how many microns of coating we have applied. it is important to give at least 5 coats by brush to make sure it is covered with +300 microns of paint.

If we under-apply all the work have been wasted.

If we over-apply we have work that will last longer.

Gauging the coating thickness

A DFT gauge is a good tool to measure multible coats of paint.

It comes in both digital and magnetic (ex-proof) versions.

This was a short explanation to why it is important to apply a good thick coating, I hope it was easy to understand and gave practical insight to your daily work.

Feel free to use the content to explain it to the onboard crew.

If you have any comments or questions to this blog post or corrosion maintenance onboard in general feel free to comment below or send me a message.